History

Opportunities and major stages experienced in the process of enterprise development and growth.

In the course of the development of the company, we have experienced a gradual leap from scratch, from small to large, from hoses to rare earth permanent magnets to high-tech sheet metal finishing. Looking back at our development history, the problem can be explained.

At first, we seized the market opportunity and "introduced" the country's first-class military-to-civilian metal hose production technology from Shanghai, and launched the metal hose production base project. This step not only laid the foundation for our future development, but also brought us numerous honors and won the honorary title of "National Machinery and Electronic Products Export Base Enterprise".

The second is the launch of rare earth, self-propagating ceramic composite steel pipe and cold-rolled sheet projects. The reserves of rare earth resources in my country account for 90% of the world's total reserves, and rare earth products have very broad prospects for development. Our company takes full advantage of this advantage and actively launched the rare earth permanent magnet project, which has become one of our leading products with the continuous expansion of the rare earth product market.

Later, the company launched the self-propagating ceramic composite steel pipe project. This project is a key project of the national "863" plan, with high technical content and broad market. The construction of the project not only brought considerable benefits to the company, but also filled the domestic technological gap.

Finally, we aimed at the 650 cold-rolling project, which was the leading technology in China at that time. With excellent product quality and good after-sales service, Changchun FAW cooperated with us and became our long-term partner. .

Since 2003, we have adhered to the path of leading technology, and in line with the goal of becoming a bigger, stronger and better enterprise, we have continuously expanded our scale and achieved rapid development. At this stage, we have undergone earth-shaking changes and realized the sustainable development of the enterprise by leaps and bounds.

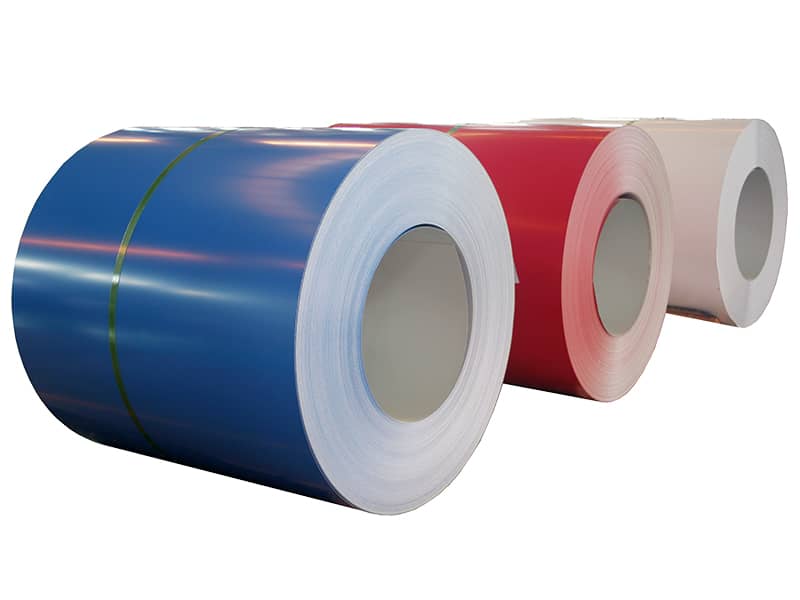

On February 16, 2004, the natural gas project with a total pipeline length of 45 kilometers was officially ventilated and ignited by our company. On March 19, 2004, the galvanized sheet project with an annual output of 300,000 tons was officially put into operation. On June 6 The color-coated sheet project with an annual output of 200,000 tons was completed and put into operation, and the first phase of the project was all put into operation, which achieved good benefits that year.

On December 12, 2005, the company's production line of 1450 cold-rolled sheet with an annual output of 600,000 tons was officially put into operation. At the same time, the joint venture thermal power plant project was completed to generate electricity, which ensured the power supply of the cold-rolled sheet project and greatly reduced the product cost. It has realized the production pattern of "integration of three plates", and has become one of the few production enterprises in our province and even in the country that has cold-rolled, galvanized and color-coated plates at the same time.

In 2005, the company's "Hangke brand" galvanized sheet won the title of Shandong famous brand product.

In 2006, the "Guanzhou Brand" color-coated board won this honor again, and the Guanzhou trademark was also awarded the title of Shandong Famous Brand.

In 2008, 300,000 tons of aluminum-zinc-coated silicon plate production line, 2# 200,000 tons of color-coated plate production line, 300,000 tons of continuous annealed plate production line, 200,000 tons of 1450 single-machine reversible cold-rolled plate production line and 200,000 tons of production line were put into operation. 1200 single-machine reversible cold-rolled sheet production line.

In 2009, a 3# 200,000-ton color-coated sheet production line was completed and put into operation.

In 2010, the company fully implemented the doubling project, which not only doubled the production capacity, but also marked the transformation and upgrading of Guanzhou products to high-strength, deep-drawing, automobiles, home appliances and other high value-added applications.

In 2011, 2# 1,000,000 ton cold-rolled sheet production line, 3# 200,000 ton galvanized sheet production line, natural gas cracking hydrogen production and cryogenic nitrogen production were completed and put into operation.

In 2012, 2# 400,000 tons continuous annealing plate production line, 4# 300,000 tons galvanized plate production line, 4# 200,000 tons color-coated plate production line, 5# 200,000 tons color-coated plate production line, zinc oxide and 2# Environmental protection projects such as sewage treatment stations have been completed and put into operation one after another.

In 2013, a 6# 100,000-ton color-coated sheet production line with an annual output of 3,000 tons of rare earth permanent magnet materials was completed and put into operation.

In 2014, the annual output of 400,000 tons of thick plate galvanizing production line, 7# color-coated plate production line, zinc oxide production capacity enhancement project, and the Guantongda logistics center project were successively completed and put into operation.

In 2015, the 6# 300,000-ton galvanized sheet production line for home appliances, the 2# unit of the power plant, and the heating project in Guanxian urban area were completed and put into operation one after another.

At present, Guanzhou has formed an annual output of 2 million tons of cold-rolled sheets, 1.6 million tons of galvanized sheets, 1.3 million tons of color-coated sheets, 700,000 tons of annealed sheets, 3,000 tons of high-performance NdFeB rare earth permanent magnet materials and The production scale of 10,000 tons of zinc oxide. Focusing on "expanding production capacity, stabilizing quality, reducing cost, building brand, and increasing efficiency", the company has established a stable raw material supply and sales network with customers, enjoying a high reputation in the domestic and foreign markets. It has established long-term strategic cooperative relations with Baosteel, Shougang, Taigang, Handan Iron and Steel, Shandong Iron and Steel and other large steel groups and the world's top 500, the world's top three paint manufacturers such as Aksu, PPG, Beco and other paint manufacturers, Guanzhou color plate Successfully applied to high-speed railway station projects such as Jinan, Qingdao, Kunming, Shanghai Hongqiao, and international airport projects such as Xinjiang Hotan and Henan Xinzheng, becoming the leading enterprises in the industry such as Haier, Hisense, China National Heavy Duty Truck, COFCO, Gangzhijie, Sentexxing, etc. Long-term suppliers, products are exported to more than 40 countries and regions such as Russia, Canada, Africa, South America and Southeast Asia.