About GUANZHOU

Learn more

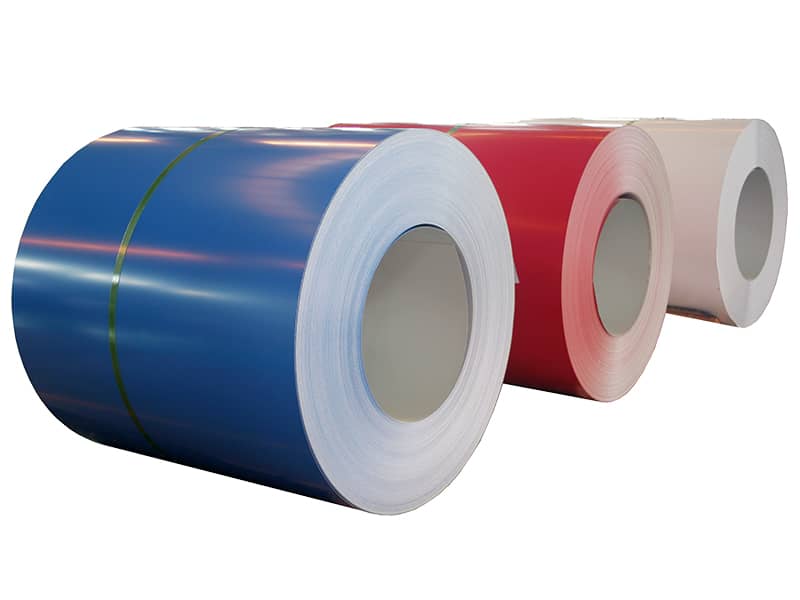

Color Coated Sheet

Pickled Sheet

Cold Rolled Sheets

Galvanized Sheet

Aluminum Zinc Plate

Zinc Aluminum Magnesium Sheet

Industry News

Company News

Color-coated sheet is based on galvanized sheet, galvalume sheet, zinc-aluminum-magnesium, aluminum-zinc-magnesium, aluminum-magnesium-manganese, stainless steel as the substrate, after surface pretreatment, using a roller coating method, coated with multiple layers of liquid paint, after baking Bake and cool.

It uses polyester, silicon-modified polyester, high-weather-resistant polyester, polyvinylidene fluoride, epoxy, and high-sealing corrosion-resistant coatings. It has excellent durability, corrosion resistance, and moldability(formability).

Products are widely used in household appliances, decoration, construction, automotive and other industries.

Color covered sheet is based totally mostly on galvanized sheet, galvalume sheet, zinc-aluminum-magnesium, aluminum-zinc-magnesium, aluminum-magnesium-manganese, stainless steel due to the fact the substrate, after ground pretreatment, the usage of a roller coating method, protected with multiple layers of liquid paint, after baking Bake and cool.It uses polyester, silicon-modified polyester, high-weather-resistant polyester, polyvinylidene fluoride, epoxy, and high-sealing corrosion-resistant coatings. It has terrific durability, corrosion resistance, and moldability(formability). Products are extensively applied in own circle of relatives appliances, decoration, construction, vehicle and extraordinary industries.

The cold rolled sheet has excellent shape and ground quality , and the ground is straightforward and bright , and has many varieties . It iswidely applied in automobiles , home appliances , packaging containers , enamel , introduction and exclusive industries

Product Name | Film thicknessμm | Core performance | T bend | MEK | Neutral salt spray | QUV-A | Recommended environment |

Self-cleaning products | ≥25 | Carbon black experiment △E<2, water contact angle ≥30 degrees | 2T | ≥100 | 1000 h | 3000 h | C3 level environment |

Heat reflection products | ≥25 | TSR≥0.25,SRI:Light color≥78,other colours≥29 | 2T | ≥100 | 1000 h | 1500 h | C3 level environment |

Anti-static products | ≥25 | Surface resistance 1066-1099Ω | 2T | ≥100 | 1000 h | 1500 h | C2 level environment |

Antibacterial products | ≥25 | Activity against Staphylococcus aureus and E. coli>2 | 2T | ≥100 | 1000 h | 1500 h | C2 level environment |

Type of coating | Recommended substrate type | Coating thicknessμm | MEK | T bend | Porosity | 5%hydrochloric acid | 5%Sodium hydroxide | Neutral salt spray | Acid salt spray | Alkaline salt spray | QUV-A | Common environment | Dedicated environment | Recommended environment |

Polyester(PE) | Z/AZ/ZM/AZM | ≥20 | ≥100 | 3T | / | 24 h | 24 h | 1000h | / | / | 1000 h | 10 year | / | C2 environment |

High weather resistance(HDP) | Z/AZ/ZM/AZM | ≥23 | ≥100 | 3T | / | 24 h | 24 h | 1500h | / | / | 1500 h | 15 year | / | C3 environment |

Silicon Reform(SMP) | Z/AZ/ZM/AZM | ≥23 | ≥100 | 3T | / | 24 h | 24 h | 1500h | / | / | 1500 h | 15 year | / | C2 environment |

Fluorocarbon(PVDF) | Z/AZ/ZM/AZM | ≥25 | ≥100 | 2T | / | 24 h | 24 h | 2000h | / | / | 3000 h | 20~30 year | / | C4 environment |

Polyurethane(PU) | Z/AZ/ZM/AZM | ≥40 | ≥100 | 2T | / | 24 h | 24 h | 720h | / | / | 1000 h | 10~20 year | / | C2 environment |

Hot film(VCM) | Z/AZ/ZM/AZM | ≥100 | / | 0T | / | 360 h | / | / | / | / | / | 10 year | / | C2 environment |

Color printing | Z/AZ/ZM/AZM | ≥25 | ≥100 | 3T | / | 24 h | 24 h | 600h | / | / | 1000 h | 10 year | / | C2 environment |

Reticulated, suede | Z/AZ/ZM/AZM | ≥25 | ≥100 | 2T | / | 24 h | 24 h | 1000h | / | / | 1000 h | 10 year | / | C2 environment |

High corrosion-resistant polyester | Z/ZM/AZM | ≥25 | ≥1000 | 3T | 90V No breakdown | 120 h | 120 h | 2000h | 1500 h | 1500 h | 2000 h | 15 year | 10 year | C5 environment |

High corrosion resistance and weather resistance polyester(HDP•Pro) | Z/ZM/AZM | ≥25 | ≥1000 | 3T | 90V No breakdown | 120 h | 120 h | 2500h | 2000 h | 2000 h | 3000 h | 20 year | 15 year | C5 environment |

Super corrosion resistant super weather resistant polyester(HDP•Plus) | Z/ZM/AZM | ≥30 | ≥1000 | 3T | 90V No breakdown | 360 h | 360 h | 4000h | 3000 h | 3000 h | 4000 h | 25 year | 20 year | C5 environment |

High corrosion resistance fluorocarbon aluminum magnesium manganese(PVDF•Pro) | Aluminum magnesium manganese | ≥25 | ≥1000 | 2T | 90V No breakdown | 240 h | 240 h | 10000h | 5000 h | 5000 h | 10000 h | 50 year | / | Key industrial engineering, |

Super corrosion-resistant nano-fluorocarbon aluminum magnesium manganese(PVDF•Plus) | Aluminum magnesium manganese | ≥30 | ≥1000 | 2T | 90V No breakdown | 480 h | 480 h | 20000h | 10000 h | 10000 h | 15000 h | 70 year | / | Key industrial engineering, |

Centennial stainless steel fluorocarbon(PVDF•Plus) | Stainless steel | ≥30 | ≥1000 | 2T | 90V No breakdown | 480 h | 480 h | 30000h | 10000 h | 10000 h | 15000 h | 100 year | / | Key industrial engineering, |

High corrosion-resistant epoxy back paint | / | ≥12 | ≥100 | 4T | 67.5V No breakdown | 120 h | 120 h | 2000h | 1500 h | 1500 h | / | / | / | Supporting the use of |

Super corrosion-resistant epoxy back paint | / | ≥20 | ≥100 | 3T | 90V No breakdown | 240 h | 240 h | 3000 h | 2500 h | 2500 h | 2000 h | / | / | Supporting the use of |