The aluminum-zinc-plated metallic alloy coating includes about 55% aluminum, about 43.5% zinc, and about 1.5% silicon. Compared with traditional galvanized products, it has more top notch corrosion resistance, warm temperature resistance, warm temperature reflectivity and extraordinary characteristics. The zinc flower(spangle) on the ground of the aluminum-plated zinc plate is small and uniform, with brilliant colours and immoderate ground hardness.

Contact Now

The composition of the plating answer of aluminum zinc magnesium and zinc aluminum magnesium board is 2% magnesium brought on the idea of zinc and aluminum, which has brilliant notch safety overall performance as compared with different coating merchandise.The zinc flowers(spangle) at the floor of aluminum zinc magnesium and zinc aluminum magnesium plates are delicate, beautiful, and feature proper corrosion resistance.

Contact Now

The composition of the plating answer of aluminum zinc magnesium and zinc aluminum magnesium board is 2% magnesium delivered on the premise of zinc and aluminum, which has remarkable notch safety overall performance as compared with different coating merchandise.The zinc flowers(spangle) at the floor of aluminum zinc magnesium and zinc aluminum magnesium plates are delicate, beautiful, and feature proper corrosion resistance.

Contact Now

The composition of the plating solution of aluminum zinc magnesium and zinc aluminum magnesium board is 2% magnesium added on the idea of zinc and aluminum, which has awesome notch protection general overall performance compared with exclusive coating products.The zinc flowers(spangle) on the ground of aluminum zinc magnesium and zinc aluminum magnesium plates are delicate, beautiful, and characteristic right corrosion resistance.

Contact Now

The composition of the plating solution of aluminum zinc magnesium and zinc aluminum magnesium board is 2% magnesium introduced at the concept of zinc and aluminum, which has extremely good notch protection ordinary ordinary normal overall performance in assessment with exceptional coating products.The zinc flowers(spangle) on the ground of aluminum zinc magnesium and zinc aluminum magnesium plates are delicate, beautiful, and function right corrosion resistance.

Contact Now

The composition of the plating solution of aluminum zinc magnesium and zinc aluminum magnesium board is 2% magnesium delivered at the concept of zinc and aluminum, which has awesome notch protection normal overall performance compared with exclusive coating products.The zinc flowers(spangle) on the ground of aluminum zinc magnesium and zinc aluminum magnesium plates are delicate, beautiful, and function right corrosion resistance.

Contact Now

The composition of the plating solution of aluminum zinc magnesium and zinc aluminum magnesium board is 2% magnesium added on the basis of zinc and aluminum, which has excellent notch protection performance compared with other coating products.The zinc flowers(spangle) on the surface of aluminum zinc magnesium and zinc aluminum magnesium plates are delicate, beautiful, and have good corrosion resistance.

Contact Now

The composition of the plating answer of aluminum zinc magnesium and zinc aluminum magnesium board is 2% magnesium added on the idea of zinc and aluminum, which has tremendous notch safety regular typical overall performance in comparison with different coating merchandise.The zinc flowers(spangle) at the floor of aluminum zinc magnesium and zinc aluminum magnesium plates are delicate, beautiful, and feature proper corrosion resistance.

Contact Now

The composition of the plating answer of aluminum zinc magnesium and zinc aluminum magnesium board is 2% magnesium brought on the premise of zinc and aluminum, which has outstanding notch safety overall performance as compared with different coating merchandise.The zinc flowers(spangle) at the floor of aluminum zinc magnesium and zinc aluminum magnesium plates are delicate, beautiful, and feature exact corrosion resistance.

Contact Now

The composition of the plating answer of aluminum zinc magnesium and zinc aluminum magnesium board is 2% magnesium brought on the idea of zinc and aluminum, which has exquisite notch safety regular regular ordinary universal overall performance in evaluation with fantastic coating merchandise.The zinc flowers(spangle) at the floor of aluminum zinc magnesium and zinc aluminum magnesium plates are delicate, beautiful, and characteristic proper corrosion resistance.

Contact Now

The composition of the plating solution of aluminum zinc magnesium and zinc aluminum magnesium board is 2% magnesium added at the concept of zinc and aluminum, which has notable notch protection ordinary overall performance compared with one of a kind coating products.The zinc flowers(spangle) on the ground of aluminum zinc magnesium and zinc aluminum magnesium plates are delicate, beautiful, and characteristic right corrosion resistance.

Contact Now

The aluminum-zinc-plated metallic alloy coating consists of approximately 55% aluminum, approximately 43.5% zinc, and approximately 1.5% silicon. Compared with conventional galvanized products, it has extra terrific corrosion resistance, warmth resistance, warmth reflectivity and excellent characteristics. The zinc flower(spangle) at the floor of the aluminum-plated zinc plate is small and uniform, with colorful solar sun shades and excessive floor hardness.

Contact Now

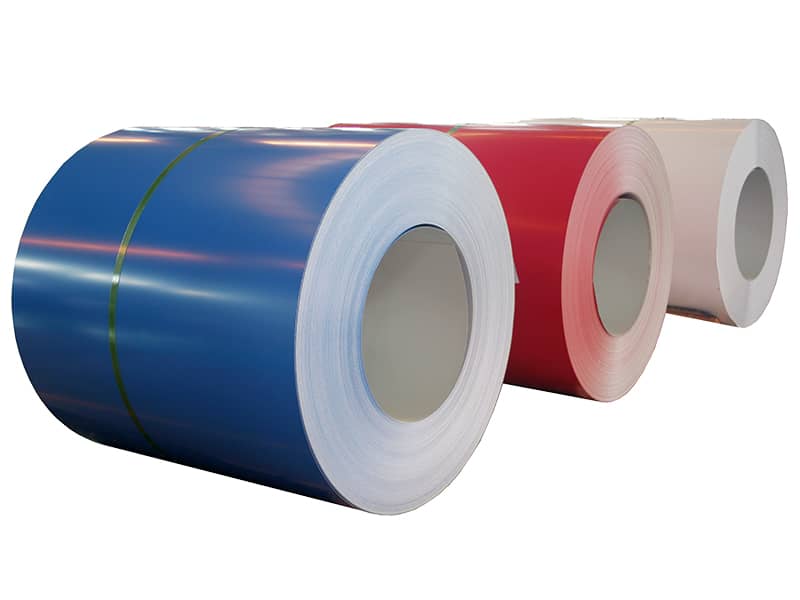

Color covered sheet is primarily based totally honestly totally on galvanized sheet, galvalume sheet, zinc-aluminum-magnesium, aluminum-zinc-magnesium, aluminum-magnesium-manganese, chrome steel because of the reality the substrate, after floor pretreatment, the use of a curler coating method, included with more than one layers of liquid paint, after baking Bake and cool.It makes use of polyester, silicon-changed polyester, high-weather-resistant polyester, polyvinylidene fluoride, epoxy, and high-sealing corrosion-resistant coatings.

Contact Now

The aluminum-zinc-plated metal alloy coating consists of approximately 55% aluminum, approximately 43.5% zinc, and approximately 1.5% silicon. Compared with conventional galvanized products, it has extra terrific corrosion resistance, warmth resistance, warmth reflectivity and different characteristics. The zinc flower(spangle) at the floor of the aluminum-plated zinc plate is small and uniform, with shiny colorings and excessive floor hardness.

Contact Now

The aluminum-zinc-plated metal alloy coating includes about 55% aluminum, about 43.5% zinc, and about 1.5% silicon. Compared with traditional galvanized products, it has more super corrosion resistance, warm temperature resistance, warm temperature reflectivity and one of a kind characteristics. The zinc flower(spangle) on the ground of the aluminum-plated zinc plate is small and uniform, with colourful sun sunglasses and immoderate ground hardness.

Contact Now

Hot-dip galvanized and zinc-iron alloys have notable performances, correct corrosion resistance, forming, coating and one of a kind whole properties, and are especially applied in introduction, own circle of relatives appliances, automobiles, and metallurgy industries.Among them, being especially used for roofs, doors and windows, shutter doors, ceiling keels, and so forth withinside the introduction industry.; being applied in refrigerators in Home appliances, washing machines, and so forth.; being especially used for body shells, chassis, doors, fuel tanks, fenders, and so

Contact Now

The aluminum-zinc-plated steel alloy coating is composed of about 55% aluminum, about 43.5% zinc, and about 1.5% silicon. Compared with traditional galvanized products, it has more excellent corrosion resistance, heat resistance, heat reflectivity and other characteristics. The zinc flower(spangle) on the surface of the aluminum-plated zinc plate is small and uniform, with bright colors and high surface hardness.

Contact Now

The aluminum-zinc-plated metallic alloy coating consists of approximately 55% aluminum, approximately 43.5% zinc, and approximately 1.5% silicon. Compared with conventional galvanized products, it has extra great corrosion resistance, warmth resistance, warmth reflectivity and different characteristics. The zinc flower(spangle) at the floor of the aluminum-plated zinc plate is small and uniform, with vibrant shades and excessive floor hardness.

Contact Now

The aluminum-zinc-plated metallic alloy coating consists of approximately 55% aluminum, approximately 43.5% zinc, and approximately 1.5% silicon. Compared with conventional galvanized products, it has greater exceptional corrosion resistance, warmth resistance, warmth reflectivity and one in every of a type characteristics. The zinc flower(spangle) at the floor of the aluminum-plated zinc plate is small and uniform, with colorful solar sun shades and excessive floor hardness.

Contact Now

The aluminum-zinc-plated steel alloy coating includes about 55% aluminum, about 43.5% zinc, and about 1.5% silicon. Compared with traditional galvanized products, it has greater amazing corrosion resistance, warm temperature resistance, warm temperature reflectivity and extraordinary characteristics. The zinc flower(spangle) on the ground of the aluminum-plated zinc plate is small and uniform, with colourful sun sunglasses and immoderate ground hardness.

Contact Now

The aluminum-zinc-plated metal alloy coating includes about 55% aluminum, about 43.5% zinc, and about 1.5% silicon. Compared with traditional galvanized products, it has more fantastic corrosion resistance, warm temperature resistance, warm temperature reflectivity and one in each of a kind characteristics. The zinc flower(spangle) on the ground of the aluminum-plated zinc plate is small and uniform, with colourful sun solar sun sunglasses and immoderate ground hardness.

Contact Now

The aluminum-zinc-plated steel alloy coating consists of approximately 55% aluminum, approximately 43.5% zinc, and approximately 1.5% silicon. Compared with conventional galvanized products, it has extra terrific corrosion resistance, warmth resistance, warmth reflectivity and one in every of a type characteristics. The zinc flower(spangle) at the floor of the aluminum-plated zinc plate is small and uniform, with colorful solar sun solar sun shades and excessive floor hardness.

Contact Now

Hot-dip galvanized and zinc-iron alloys have great performances, accurate corrosion resistance, forming, coating and different complete properties, and are in particular utilized in creation, family appliances, automobiles, and metallurgy industries.Among them, being in particular used for roofs, doorways and windows, shutter doorways, ceiling keels, and so on withinside the creation industry.; being utilized in fridges in Home appliances, washing machines, and so on.; being in particular used for frame shells, chassis, doorways, gasoline tanks, fenders, and so on withinside

Contact Now

Color covered sheet is primarily based totally in reality honestly totally on galvanized sheet, galvalume sheet, zinc-aluminum-magnesium, aluminum-zinc-magnesium, aluminum-magnesium-manganese, chrome steel because of the truth the substrate, after floor pretreatment, the usage of a curler coating method, protected with multiple layers of liquid paint, after baking Bake and cool.It makes use of polyester, silicon-changed polyester, high-weather-resistant polyester, polyvinylidene fluoride, epoxy, and high-sealing corrosion-resistant coatings.

Contact Now